Effective Ways to Troubleshoot Common Issues in Packaging Equipment Procedure

In the world of manufacturing and production, making sure the smooth operation of product packaging machines is vital to keeping efficiency and meeting target dates. Let's discover some reliable methods that can assist in quickly solving usual troubles in product packaging maker operation.

Identifying Common Product Packaging Equipment Problems

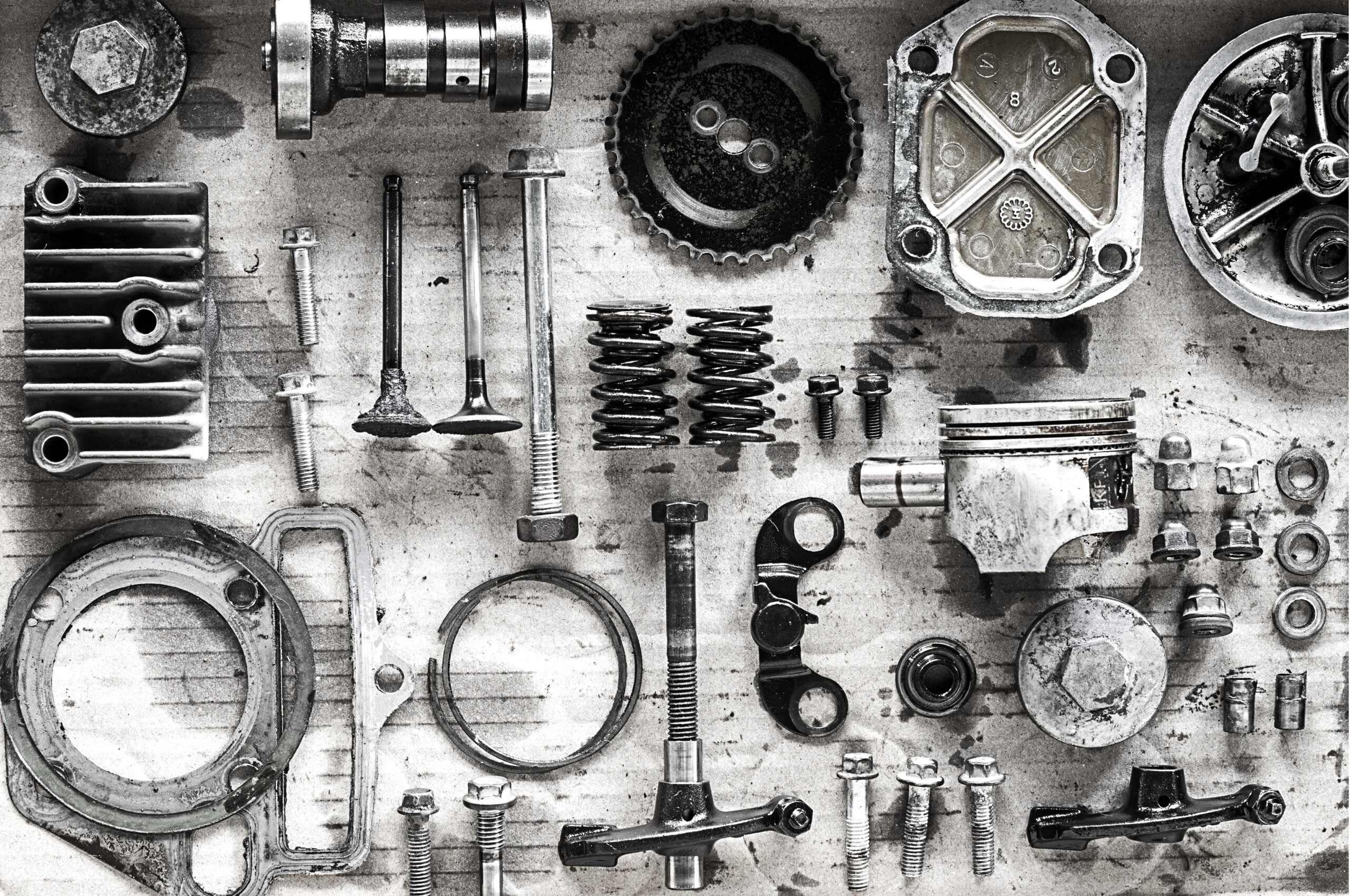

When troubleshooting packaging equipment troubles, it is vital to accurately identify usual problems that may arise during the product packaging procedure. One common problem experienced in product packaging equipments is inappropriate sealing. This can lead to products not being securely packaged, running the risk of damages or contamination throughout transport. One more regular issue is misalignment, where the product packaging materials or products are not appropriately straightened, causing jams or misfeeds. Furthermore, mechanical wear and tear on elements like belts, gears, or chains can lead to irregular packaging or equipment breakdowns.

Electric problems, such as malfunctioning circuitry or power supply problems, are likewise common perpetrators behind product packaging device failures. By determining these concerns early on, drivers can prevent downtime, decrease product waste, and make certain the smooth performance of packaging equipment.

Executing Routine Maintenance Checks

Regularly performing detailed upkeep checks is crucial for making sure the optimal efficiency and durability of packaging makers. In addition, checking and adjusting setups associated to pressure, speed, and temperature can help keep the device's effectiveness and accuracy.

Furthermore, conducting routine inspections of electric links and controls can aid prevent electric breakdowns and make sure the safety of the device drivers. Recording upkeep tasks and maintaining detailed records of components substitutes and fixings can aid in tracking the device's efficiency over time and determining any type of reoccuring concerns. Ultimately, a proactive approach to routine upkeep checks is paramount in taking full advantage of the performance and integrity of packaging devices.

Repairing Mechanical and electric Troubles

Effective troubleshooting of mechanical and electrical problems in packaging equipments needs a methodical approach and a deep understanding of the equipment's components and operation. When encountering electric concerns, beginning by inspecting power sources, connections, and control panels for any noticeable damage or loosened connections. Utilizing a multimeter can assist recognize electric faults such as brief circuits or open circuits. Furthermore, evaluating read this article sensors, actuators, and communicates for proper functionality is critical in diagnosing electric breakdowns precisely.

Lubrication of key parts can avoid friction-related problems and make certain smooth maker operation. Validating the placement of elements and adjusting stress where required can rectify issues connected to misalignments or irregular motions in the packaging machine.

Optimizing Device Setups for Efficiency

To boost the overall efficiency of product packaging devices, an essential element involves fine-tuning and maximizing maker settings for optimal effectiveness and output uniformity. Appropriately calibrated equipment setups can considerably influence the speed, precision, and high quality of the packaging procedure. On a regular basis keeping track of and adjusting these maker Discover More Here settings based on the certain requirements of the product packaging materials and item can lead to boosted efficiency, lowered downtime, and enhanced total outcome quality.

Applying Precautionary Upkeep Steps

Applying preventative maintenance steps is important for making sure the long life and optimum efficiency of packaging equipments in industrial settings. This timetable ought to be complied with faithfully by experienced upkeep workers to guarantee that the makers operate at peak efficiency.

In addition to set up upkeep, it is vital to maintain extensive documents of all maintenance activities performed on the find here product packaging makers. These records can offer valuable insights right into the devices' performance fads, assistance identify reoccuring problems, and guide future upkeep efforts - packaging machine repair. In addition, purchasing training programs for machine drivers and maintenance team on appropriate maintenance treatments and methods can considerably boost the efficiency of preventive upkeep measures. By focusing on precautionary upkeep, companies can lengthen the lifespan of their product packaging devices, decrease interruptions in manufacturing, and maintain consistent item quality.

Final Thought

Finally, efficient troubleshooting of usual concerns in product packaging device procedure involves determining issues, doing regular upkeep checks, troubleshooting electric and mechanical problems, enhancing device setups for effectiveness, and applying precautionary maintenance steps. By complying with these actions, operators can guarantee smooth and dependable procedure of product packaging equipments, decreasing downtime and making best use of productivity.

When repairing product packaging device issues, it is important to properly determine common issues that may arise throughout the packaging process.Reliable troubleshooting of mechanical and electrical problems in packaging machines needs a methodical strategy and a deep understanding of the machine's parts and procedure.To improve the overall performance of packaging devices, a critical element involves fine-tuning and optimizing maker settings for maximum performance and output uniformity.Carrying out precautionary upkeep steps is critical for guaranteeing the long life and ideal performance of product packaging devices in commercial settings.In enhancement to scheduled upkeep, it is vital to maintain detailed records of all upkeep tasks done on the packaging makers.

Comments on “Indications Your Packaging Machine Requirements Immediate Repair”